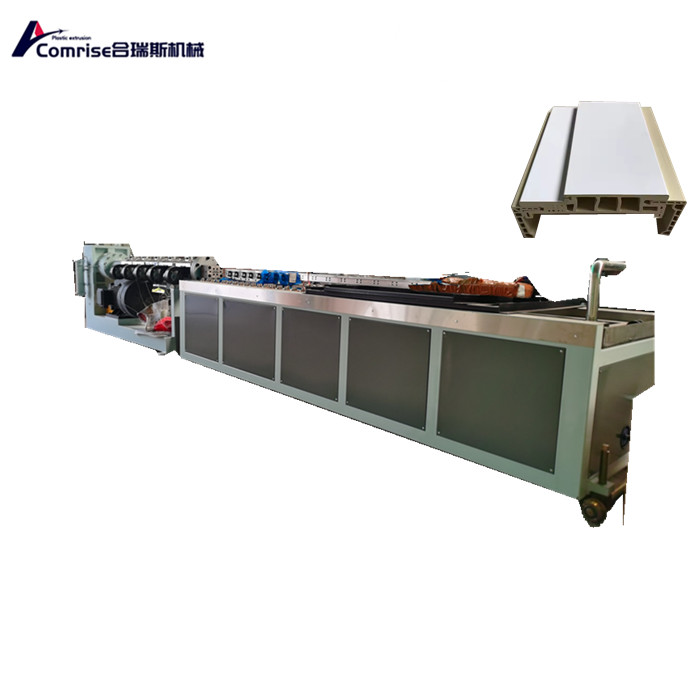

UPVC PVC -Türpanel und Fensterprofil Produktionslinie

Anfrage absenden

The PVC door production line is mainly used to produce PVC plastic profiles with different cross-sectional shapes and heights. The surface of PVC profiles/panels can be treated by printing and coating with glossy oil, heat transfer printing, or lamination, which can be used for kitchens, bathrooms, balconies, and more.

characteristic

1. Different models of conical twin-screw extruders are suitable for high-speed extrusion of different plate widths.

2. According to different molds, the forming table can be selected in specifications such as 6 meters, 8 meters, etc. Vacuum shaping adopts a special eddy current cooling system for easy cooling and shaping to meet the needs of high-speed extrusion.

3. The tractor adopts our company's unique lifting technology, which works smoothly, has good reliability, and has high traction force.

4. The movement speed of the cutting machine is synchronized with the traction speed.

By polishing, hot stamping, laminating, and vacuum shaping, users can make the WPC facade look more like real wood.

UPVC PVC Door Panel And Window Profile Production Line:

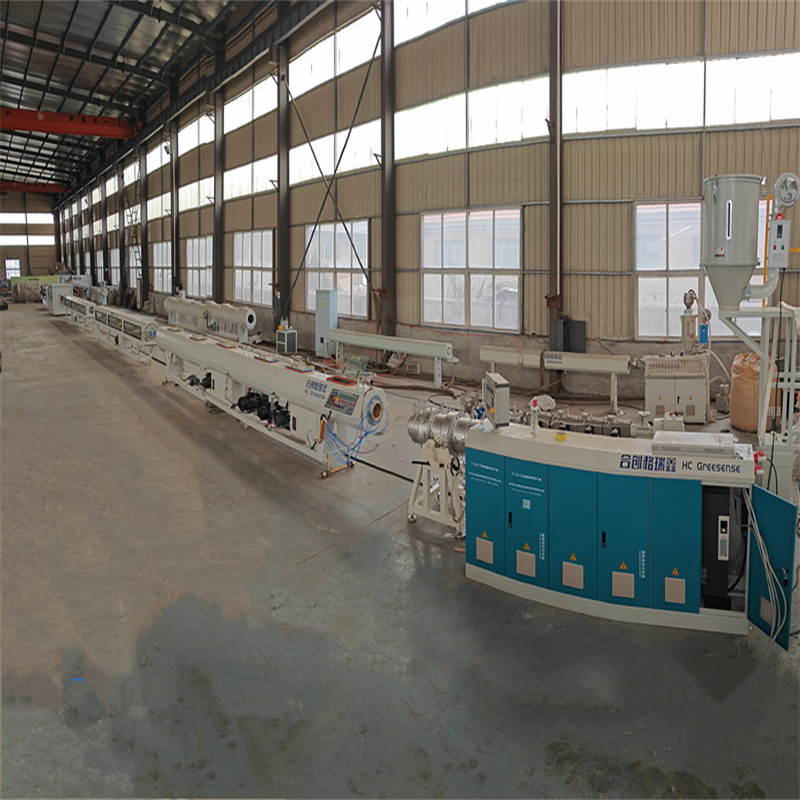

Mixer → Loader → Extruder → Mold → Vacuum Calibration Platform → Cooling Bracket → Dragging

Machine → cutting machine (with dust collector) → stacker crane → packaging → crusher, pulverizer (waste)

Production Line Details

name: SJZ92/188 Spiral Feeding Machine

Technical parameters:

a. Main motor power: 1.5kw

b. Pipeline length: 1100 millimetersname: SJZ92/188 cone extruderTechnical parameters:

a、 Main motor: 110KW Siemens/WEG brand.

b. Screw tube: 38CrMoAl, hardness HV950 or higher,

High efficiency and long service life.

Name: Extrusion and Calibration Mold

Technical parameters:

3Cr17, forged, quenched and tempered, has the characteristics of wear resistance, corrosion resistance, high strength, high precision and long-term use

Name: Polyvinyl chloride wood plastic door panel calibrat

Technical parameters:

a. Up and down, left and right manual adjustment

b. Equipped with an infrared device to ensure synchronization between speed and traction speed.

Name: PVC wood plastic door panel tractor

Technical parameters:

a. Rubber blocks are soft materials.

b. We chose Geax motors and controlled two sets of motors through a frequency converter, which means confirming the precise operation of both arms.

Name: PVC wood plastic door panel cutting machine

Technical parameters:

a. Cylinder controlled movement, fixed length cutting, high-precision cutting power using Autonics instrument for fixed length: 3kw, equipped with dust collection device

b. Equipped with electrical devices to ensure accurate cutting

Name: Plastic Extruder Frequency

Technical parameters:

ABB /SiemensName: Plastic door panel extrusion cabinetTechnical parameters:

Well arranged electrical components and well-known electrical components.

Name: PVC wood plastic door panel motor

Technical parameters:

a. This motor is 55KW, and we use Siemens brands.

b. Can be used for a long time without any changes.

Name: Cooling and shaping

Upgraded cooling and shaping system for faster cooling speed and better shaping effect

GET A QUOTATION NOW